When you’re thinking about a DIY project for your backyard… one of the first steps is to gather your material list.

If you’re not already familiar with suitable materials for your planned projects… you’ll need to do some research on the best options. (Hence, why you’re here!)

For the purposes of this article, we’re just honing in on cement board for outdoor use.

Is cement board truly suitable for the outdoor environment?

This is often assumed to be the case… but perhaps there’s more to the story than you were initially told.

And that’s exactly the topic we’re about to explore.

Ready to dive in?

What Outdoor Projects are Cement Board Used for?

If you’re looking at using exterior cement board for an outdoor project… there’s a 99% chance you’re considering it for an outdoor kitchen project.

Far and away… an outdoor kitchen is the most common backyard project you may use cement board for.

There are some cases here and there for a fire pit application. But that’s fringe!

So for this reason… this article will hyper focus on cement board as it relates to an outdoor kitchen project.

Now that we’ve laid the groundwork, let’s dig into the meat of the topic.

Not All Cement Board is Made Equal: Buyer Beware

Just like anything else you may buy… quality between brands can vary greatly.

In some regards, you could read the labels of cement board products like you would a food ingredients list.

Is the product pure? Or is it packed with fillers that’ll wreck your health in the long run? (Or, in the case of your kitchen… make it fall apart quicker?)

The more cement you see listed in the ingredients list… the better the product will be.

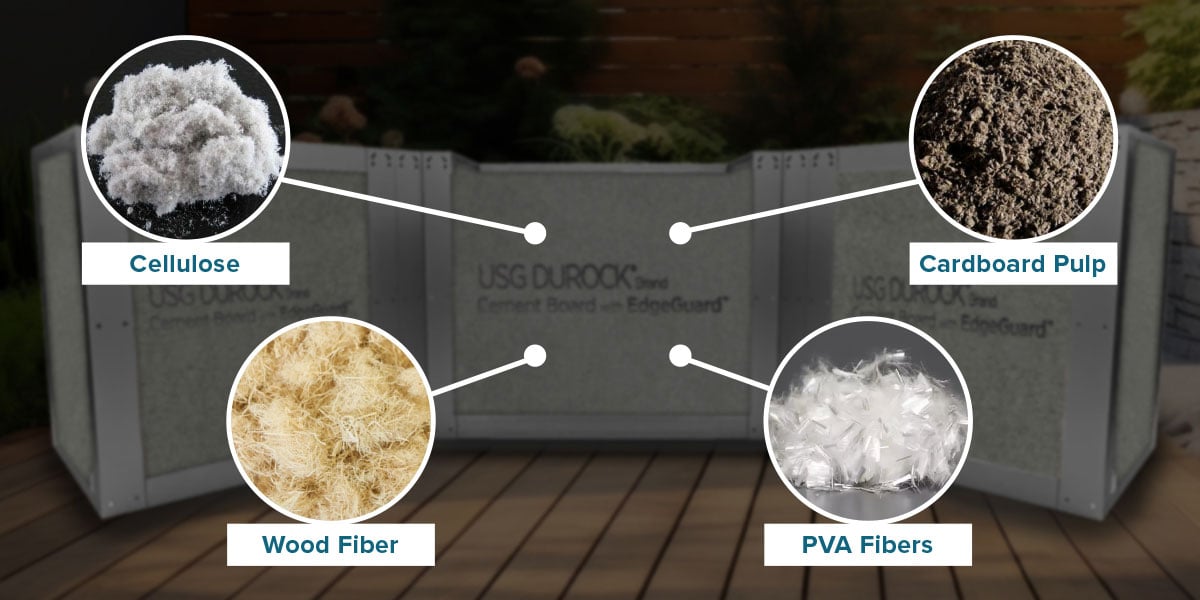

Be wary of seeing high percentages of things like “fillers”, “cellulose”, or “waste cardboard pulp paper”.

Not only are these cheap materials that won’t last long… if not properly treated, they’re also highly flammable. (Not exactly a great combo for an outdoor kitchen!)

Unfortunately, the ingredient makeup of cement board is just the starting point. There’s a whole host of other problems that come with this material!

Problematic Properties of Cement Board

Although use of concrete board in an outdoor kitchen is quite common… that doesn’t mean this material is problem-free!

In fact, there are many reasons why you should avoid using cement board at all.

If you haven’t already picked up on it… we’re pretty bearish about cement board for outdoor use. Here’s why.

Highly Permeable

First and foremost, cement backer board is a highly permeable material.

Depending on the brand you choose… the absorption rate can be as high as 14%! (Brands like Durock and Hardiebacker should have this information available online.)

Why does this matter?

Well, this high permeability means that cement board will readily absorb water.

And if you think about it for a moment… it’s pretty easy to see how that would pose a problem for your outdoor kitchen.

If your island is framed with wood, you’re going to be exposing those materials to constant moisture.

In the case of wood… you’ll end up with warping, swelling, and even rotting.

In the case of metal… you’ll get rust and corrosion over time.

That doesn’t sound like an optimal outcome for longevity, does it? We’re afraid not.

Manufacturers Recommend No Ground Contact

To double down on the fact that moisture absorption is a problem… many cement board substrate manufacturers recommend avoiding ground contact with their product.

Because if your cement board sheathing is touching the ground… it’ll easily wick up moisture like a sponge.

Every time it rains, your outdoor kitchen will be taking on water!

Of course, if you follow the manufacturer’s guidelines and don’t let the boards touch the ground… you will minimize this effect.

That said, this recommendation alone gives us pause about cement board’s durability for a BBQ island.

Waterproof Membrane May be Required

And as if the previous concerns weren’t enough… many manufacturers will also recommend using a waterproof membrane when using fiber cement board outside.

Unfortunately… this little bit of fine print is often overlooked. And as such, most DIYers don’t add a waterproof membrane to their cement board!

This extra moisture resistance is critical… and it’s exactly why you’ll see this technique used for interior applications like bathrooms.

But once again… the manufacturer’s recommendations show how precarious using cement board outdoors can actually be.

Moisture is always in the air. So when you use cement board in your outdoor kitchen… you’re always in a losing battle with the elements.

A Disaster in Many Climates

As we’ve already established… moisture absorption is a serious problem for cement board in exterior applications.

And while all climates will pose a problem… there are some climates that fare far worse than others.

Areas with high humidity and freeze thaw cycles will be the worst contenders.

Why is this?

Well, high humidity is a bit more straightforward. Extra moisture in the atmosphere will only compound the existing permeability issues with cement board.

This excess moisture will cause the cement board to expand… which puts pressure on the other layers of your outdoor kitchen, namely the frame and finish.

A metal framed outdoor kitchen is solid on its own. Therefore, all that pressure is going to be exerted on the finish… leading to stones popping off, and stucco getting cracked.

It’s unsightly and requires ongoing maintenance, yes. But even worse than that… all those newly created holes will allow the weather to wreak further havoc on your island.

If you live in a climate with frequent freeze thaw cycles, the issue is exacerbated. Excess moisture coupled with frequent temperature fluctuations will only make the damage happen quicker.

Point is, if you live in one of the aforementioned climates… in our minds, cement board is an absolute no-go for your outdoor kitchen.

Want to Steer Away from Cement Board?

Looking to the Science

At this point, you may think that we’re just casting aspersions… but there are some studies that affirm the problems with cement board for exterior use.

Let’s take a closer look.

Freeze Thaw Study

Speaking of freeze thaw climates… there was a study completed in 2019 to assess the impact of continental climates and temperature cyclicity on cement board.

5 different cement board brands were put to the test… each one enduring 1–10 freeze thaw cycles.

The samples were placed in the freezer for 1–2 hours at a temperature ranging from -11.2°F to 3.2°F.

After this, the samples were then placed in a bath at a temperature of 68°F for 1–2 hours. This process was then repeated.

This process was intended to replicate the impacts of freeze thaw cycles in a cold, northern climate.

There were several outcomes as a result of this study:

- Flexural strength of the boards decreased by 35–50%

- The crystalline bonds of the cement matrix structural lattice were weakened due to partial dissolving

- Rigidity of the boards was completely lost

As you can see… consistent temperature fluctuations led to the boards becoming brittle and inflexible.

This weakening over time will lead to significant problems with your outdoor kitchen!

But that’s not the only study to keep in mind.

High Heat Study

In 2019 and 2022, studies were conducted to understand the environmental thermal impact on the structural properties of cement board.

Once again, 5 different brands of cement board were tested during the course of this study.

Each sample was placed into a 230°C (446°F) electric oven for 3 hours.

And while this level of heat may seem excessive… this was intended to simulate the heat coming off a grill during a several hour cooking session. (Which is well-within the realm of possibility!)

After this test, several outcomes were observed:

- Carbonization and the fibers was discovered

- Most of the fibers melted or burned out

- The cement particles and structure of the matrix was found to be more granular and separated

- The material overall became brittle

Even through the regular use of your grill… this heat output will easily cause damage to your cement board over a short period of time.

Why This is a Problem for Your Outdoor Kitchen

So when you put all the pieces together… why is this such a problem for your outdoor kitchen?

We’ve touched on several of the issues already, but let’s refine the points further.

The freeze thaw study reveals that in most climates… cement board is simply not suitable for use in an outdoor kitchen.

Inevitable moisture exposure and temperature fluctuations can cause irreparable damage to the boards in a matter of months.

Even with that factor set aside… just regular use of your grill alone will degrade the cement board.

High heat coming from your grill, UV light radiation, and excess heat from the grill firebox can all lead to extremely hot temperatures… which will degrade the cement board over time and ruin their integrity.

Left unchecked long enough… this can cause the cement board to collapse and lead to a structural failure of your outdoor kitchen as a whole.

This is particularly problematic when you consider that the grill area requires the most structural support. It’s the heaviest component of your outdoor kitchen… it’s essential that this area doesn’t fail!

The results of these studies has led us to conclude that overall… cement board is not a suitable material for use in an outdoor kitchen. (We recommend that BBQ islands are constructed from pure concrete.)

But if you still choose to throw caution to the wind, and build an island using cement board anyway… what should you do?

If You’re Stuck on Cement Board... Do This

If you’ve got your heart set on a metal framed outdoor kitchen, and nothing else will do… there are a few ways you can delay or minimize the risk of cement board failure.

For one, look to brands that have the lowest absorption rate possible. Last we checked, Permabase products have an 8% absorption rate.

As the manufacturer recommends… avoid any ground contact at all costs! You don’t want that cement board wicking up moisture like a sponge.

Also note that unlike the metal frames, cement board is not structural. It has a minimal load bearing capacity.

So in order to reduce the load on your cement board… use a lightweight cladding material and finish.

Finally, be sure to use screws that are not prone to corrosion! For this, we recommend stainless steel.

But if the installation guide for cement board is starting to sound like a laundry list of things you don’t want to deal with…

But if You’d Rather Not Worry About it…

Consider an outdoor kitchen solution that’s done 95% of the work for you, and is free of cement board!

RTA outdoor kitchens are made with durable, weather-resistant ultra high performance concrete.

These islands are shipped to your door as solid, single-layer panels… complete with concrete or granite countertops, and premium 304 stainless steel appliances.

You don’t have to worry about slicing up cement board, slapping on a cladding material, or painstakingly placing stone veneer.

All you need to do is bolt together the panels in each corner, place the countertop, and drop in the appliances.

This outdoor kitchen system is as beginner friendly as it gets!

Best of all, RTA outdoor kitchens do not come with any of the pitfalls of cement board.

These concrete islands are impervious to the issues that come with high humidity and freeze thaw cycles… giving you peace of mind that your outdoor kitchen will make it through the winter. (It’ll get through many years of winter, in fact!)

RTA outdoor kitchens also will not be damaged by frequent exposure to high temperatures from your grill. It’s solid as a rock!

Starting to get curious about what’s possible with this system?

The best place to start is with our free online design tool. You can spin up a customized outdoor kitchen design in minutes… and get a great starting point for your project.

Give it a try, and we’ll be in touch soon!

FAQ

It is not recommended to leave cement board exposed outside! It is a porous material that can easily absorb water, which will deform and weaken the boards over time.

No, it is not okay for cement board to get wet. Water absorption causes damage to cement boards over time.

For outdoor applications, even when protected, cement board is not known for superior longevity. If you live in a climate with high humidity and a lot of precipitation, this will quickly degrade your cement board.